Collar Type Servo Auger Filler Machines

| Packing Material : | Sticky Powder & Powder |

|---|---|

| Packing Laminates : | Heat Sealable laminated Films |

| Filling Style : | Controlled by CBC / Servo Auger |

| Roll Width : | Min. 120 mm, Max - 25 mm |

| Pouch Type : | Center Seal Pouch |

| Pouch Dimension : | Width = 50 - 200 mm / Height = 65 - 300 mm |

| Electrical Supply : | 230 V /A.C/ Three Phase /50 Hz |

| Power Consumption : | 3 Kw |

| Compressed Air Required : | 6 CFM @ 6 Bar |

| Production Rate : | 30 Shots @ Minute / Varies As Per The Nature of Products & Filling Range |

| Weight : | Approx 750 Kgs |

| Machine Dimension : | L 1050 mm, W 990 mm, H 1360 mm |

Fully Pneumatic Servo Auger Filler Machine

| Packing Material : | Sticky Powder & Powder |

|---|---|

| Packing Laminates : | Heat Sealable laminated Films |

| Filling Range : | Upto 500 gms (As per requirement) |

| Filling Style : | Controlled by Auger Filler |

| Roll Width : | Min. 120 mm, Max - 425 mm |

| Pouch Type : | Center Seal Pouch |

| Pouch Dimension : | Width = 50 - 200 mm / Height = 65 - 300 mm |

| Electrical Supply : | 230 V / A.C / Three Phase / 50 Hz |

| Power Consumption : | 3 Kw |

| Compressed Air Required : | 6 CFM @ 6 Bar |

| Production Rate : | 30 Shots @ Minute / Varies As Per The Nature Of Products & Filling Range |

| Weight : | Approx 750 Kgs |

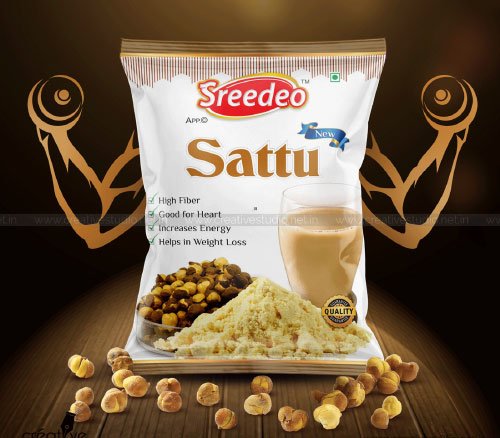

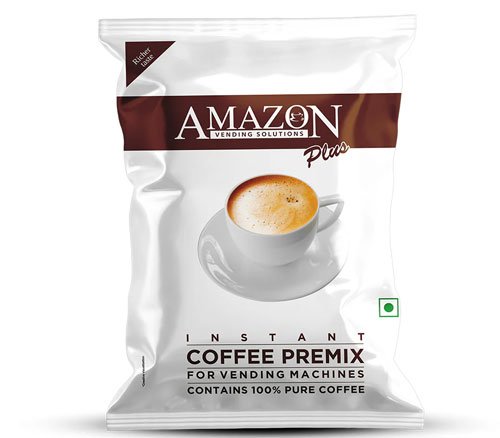

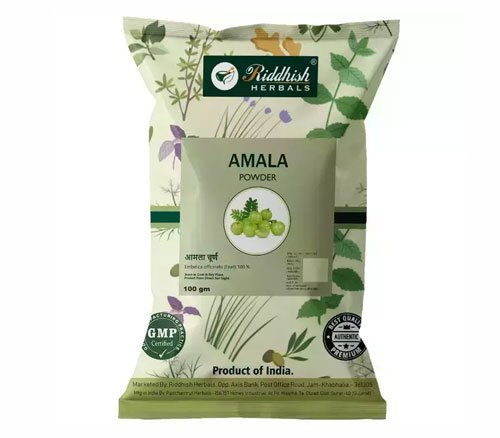

These Machines are used for Different types of Products Packaging

White Cement Powder Packing Machine Manufacturers & Dealers in India

All India Packing Machine (API) is a leading name in providing advanced White Cement Powder Packing Machine solutions for the construction and cement industry. With a focus on precision, efficiency, and durability, our machines are designed to handle bulk packing of white cement powder with minimal human intervention.

Our range includes state-of-the-art cement powder packaging equipment that ensures accurate weight measurement, uniform packing, and faster production cycles. API is recognized for delivering reliable and robust white cement packaging equipment that caters to both small-scale and large-scale manufacturers. Get top-quality White Cement Powder Packing Machine from trusted manufacturers & dealers in India. Automatic and efficient packing solutions by API.

Why Choose Automatic White Cement Packing Machines?

Automatic machines are becoming the preferred choice in the industry due to their speed, precision, and reduced labor costs. The automatic white cement packing machine from API comes with intelligent control systems, ensuring smooth operation and consistent quality. These machines can easily integrate into existing production lines, making the packaging process more efficient and cost-effective.

Our machines are engineered to:

-

Reduce wastage during the packing process

-

Ensure precise filling and sealing

-

Operate continuously for long production hours

-

Maintain hygiene and prevent contamination

Key Features of White Cement Packaging Machines

-

High Accuracy: Our machines provide precise weighing and filling, ensuring each bag contains the exact amount of white cement powder.

-

Durability: Constructed with high-quality materials, the machines offer long-lasting performance even in tough industrial environments.

-

User-Friendly Operation: With intuitive controls and minimal maintenance requirements, our machines can be operated by skilled and semi-skilled labor.

-

Flexibility: Suitable for various packaging sizes ranging from 25 kg to 50 kg bags.

-

Speed & Efficiency: The automatic packing systems enhance production capacity without compromising quality.

Trusted White Cement Packaging Machine Manufacturers

API has earned a reputation as one of the most reliable white cement packaging machine manufacturers in India. We combine innovative engineering, robust design, and advanced technology to provide solutions that meet the modern needs of cement manufacturers.

Our team works closely with clients to understand their production requirements and offer customized solutions. Whether you are looking for a standalone packing machine or a complete packaging line, API delivers machines that meet global standards.

Applications of White Cement Powder Packing Machine

Our machines are ideal for:

-

Construction material manufacturers

-

Cement factories

-

Industrial suppliers of packaged cement

-

Export-oriented cement businesses

The white cement packaging equipment ensures minimal dust emission, high operational efficiency, and compliance with safety standards. It is suitable for both domestic and international markets, providing manufacturers with a competitive edge.

Contact API for Your White Cement Packing Needs

All India Packing Machine (API) is committed to delivering the best white cement packaging solutions in India. Contact us today to get a quote, learn more about our products, or schedule a demonstration of our automatic white cement packing machine.