Powder Packing Machines

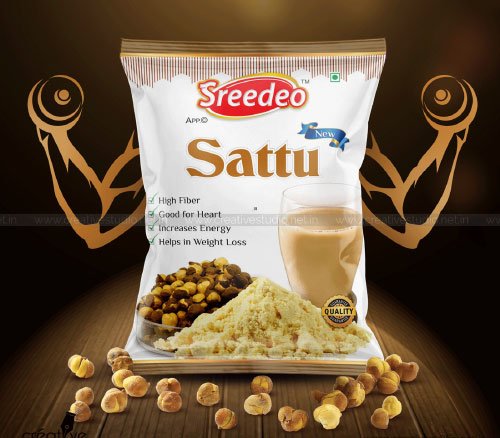

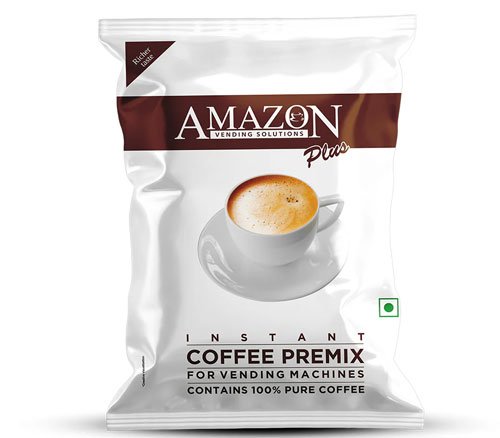

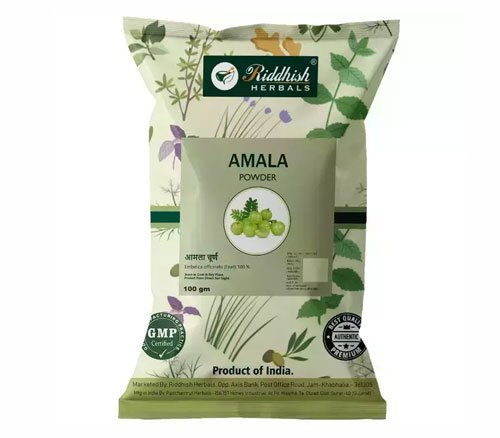

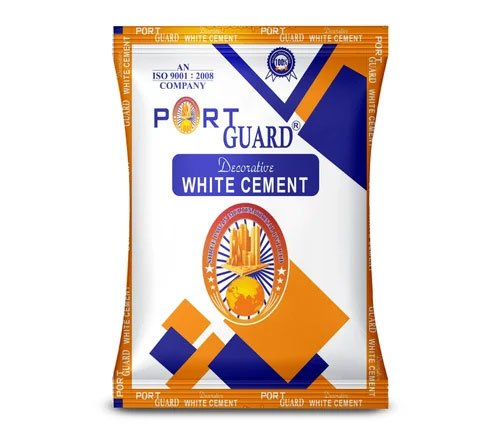

All India Packing Machines provides Powder Packing Machines, which can be used for handling all types of powder products such as spices, sugar, milk powder, coffee, and chemical powders. The machines provide accurate measurement, hygienic handling, and high speed for production in a medium to large-scale plant. Fully pneumatic, servo, and collar-type systems are available options, offering accurate filling, minimizing wastage, and ensuring consistent quality of the product. Manufactured using stainless steel contact parts and feature simple controls, our powder packing machines are ideal for food, pharmaceuticals, and chemical industries.

Features:

- Precise weighing and filling solutions

- Completely pneumatic or servo-controlled models

- Hygienic stainless steel construction

- Easy-to-use interface with touch screen or PLC control

- Applicable for VFFS and other automated packaging machines

Benefits:

- High-speed packaging for medium and large-scale production levels

- Minimizes wastage of powder and ensures accurate filling

- Straightforward cleaning and maintenance

- Multiple product types and sizes are supported

- Hygienic construction accommodates food and pharmaceutical standards

Applications:

- Packaging spices, sugar, coffee, milk powder, and chemical powders

- Food and beverage processing industries

- Chemical and pharmaceutical powder packaging

- Seamless integration with automated packing lines for continuous manufacturing